Next-Generation Modular Nuclear Reactors: The Future of Safe Energy

Modular nuclear reactors (SMRs) represent a revolutionary shift in energy generation. Unlike traditional large-scale nuclear power stations, SMRs are smaller, safer, and more flexible in deployment. As of June 2025, countries worldwide are investing in SMR development to address climate change, energy security, and the rising demand for carbon-neutral power. This article explores the technological innovations, safety advantages, global implementation progress, and potential challenges of SMRs.

Technological Advances in Modular Reactor Design

Recent developments in SMR technology have introduced scalable nuclear systems that can be built in controlled factory environments and transported to site-ready locations. These reactors typically generate between 50 to 300 megawatts of power, suitable for remote communities, industrial clusters, or integration into national grids.

Many SMRs use advanced coolants such as liquid metal or gas instead of traditional water-based cooling. These alternatives enhance thermal efficiency and reduce pressure-related risks. Moreover, several designs eliminate the need for active pumping systems, relying on natural circulation to remove heat—minimising the chance of failure during emergencies.

By adopting simplified architecture, passive safety systems, and digital monitoring, modular reactors demand less space, require fewer personnel, and can be decommissioned with lower environmental impact than conventional plants.

Examples of Cutting-Edge SMR Projects

As of mid-2025, several SMR initiatives have reached advanced stages. NuScale Power (USA) received approval from the US Nuclear Regulatory Commission for its VOYGR design, with the first operational units expected in Utah by 2029. Canada’s Ontario Power Generation is working on deploying a GE Hitachi BWRX-300 unit at the Darlington site by 2028.

In Europe, Rolls-Royce SMR has secured over £600 million in funding, planning to install up to 16 units across the UK. Their model is designed for mass production, with each unit capable of powering approximately one million homes.

Meanwhile, China has launched a high-temperature gas-cooled SMR, HTR-PM, in Shidao Bay. It became grid-connected in 2023 and serves as a template for wider deployment in Asia.

Unprecedented Safety Measures and Risk Reduction

One of the key selling points of SMRs is enhanced safety. These reactors are built with passive safety systems, meaning they can shut down safely without human intervention or electrical power. Natural convection, gravity-driven cooling, and redundant containment layers are standard.

Most modern SMRs are underground or heavily shielded to protect against external threats, including natural disasters or sabotage. This physical robustness significantly reduces vulnerabilities observed in traditional plants like Fukushima or Chernobyl.

In addition, many SMRs use low-enriched uranium or accident-tolerant fuels, which do not react aggressively under high temperatures, thereby reducing the risk of core meltdown and radioactive leakage.

How SMRs Handle Emergencies

Unlike large reactors that require complex shutdown procedures, SMRs are engineered to “fail safe.” For instance, if cooling stops, heat dissipates passively into surrounding structures. This process prevents overheating without the need for external action.

Containment systems are often modular themselves—each unit isolated from the others. If one unit fails, it does not compromise the integrity of the entire site. These features offer superior resilience against cascading failures.

Furthermore, autonomous control systems allow real-time diagnostics and early warnings, which drastically improve response times and reduce dependence on human operators during a crisis.

Deployment Outlook and Global Integration

As of June 2025, more than 80 SMR designs are under development across 20+ countries, according to the International Atomic Energy Agency. Governments are increasingly recognising SMRs as strategic assets in decarbonisation roadmaps and energy transition strategies.

In regions with unstable grids or limited space, SMRs provide stable base-load electricity and can be deployed incrementally. This modular approach makes nuclear energy more accessible to countries with limited infrastructure investment capacity.

Major collaborations are also underway. The IAEA, along with World Bank and national energy commissions, is offering support for licensing, safety validation, and funding. This international cooperation is critical to harmonising safety standards and accelerating deployment.

Integration With Renewables and Local Economies

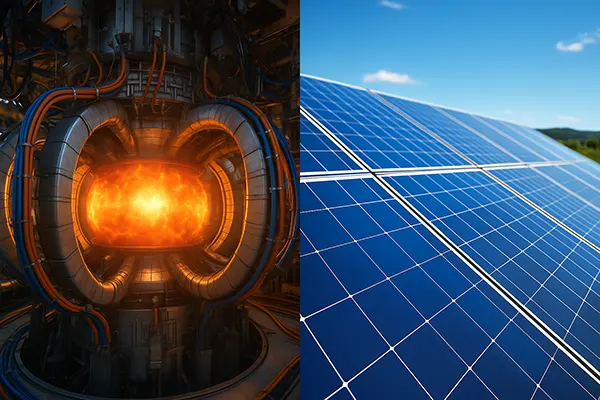

SMRs are increasingly being paired with renewables to balance intermittency. When solar or wind output drops, SMRs can quickly fill the gap, ensuring grid stability. This synergy enables nations to adopt clean energy without sacrificing reliability.

Additionally, local manufacturing of SMR components creates jobs and stimulates regional economies. Unlike massive traditional plants, SMRs can be tailored to the needs of remote mining towns, islands, or industrial zones.

In some countries like Finland and South Korea, SMRs are also being considered for district heating or desalination—highlighting their versatility beyond electricity generation alone.