Digital Twins Technology: Revolutionizing Multiple Industries

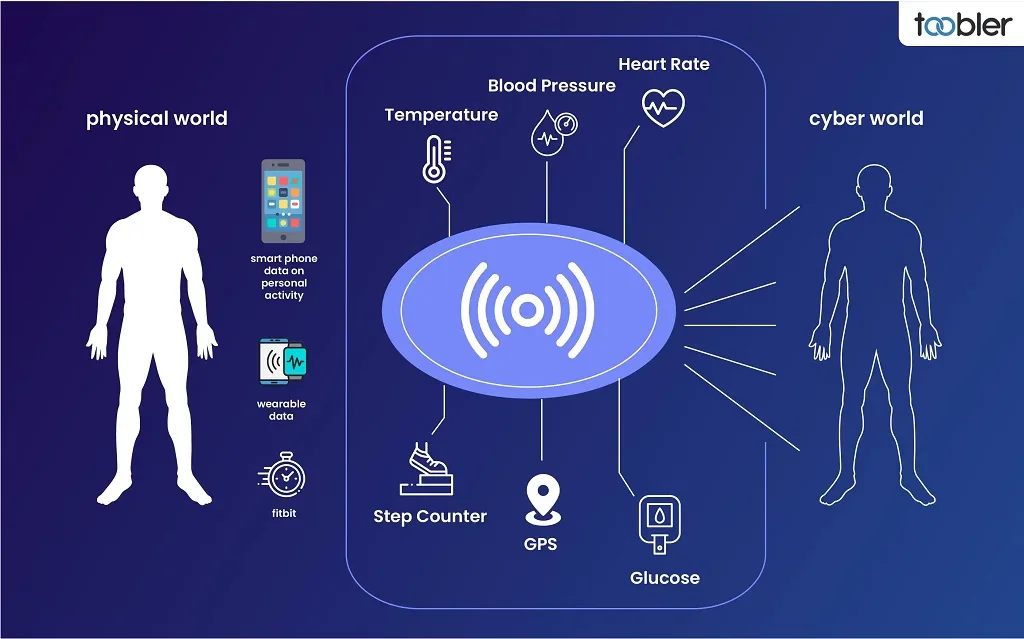

Digital twins technology represents a groundbreaking development in the realm of digital innovation. Essentially, it involves creating virtual replicas of physical assets, processes, or systems. These digital counterparts can be updated with real-time data, enabling simulation, analysis, and optimization of processes in a virtual environment before implementing them in the real world.

How Digital Twins Operate and Their Expanding Potential

The operation of digital twins is based on the integration of IoT sensors that collect real-time data from physical objects. This data is then used to update the digital replica, ensuring it reflects the current status of its physical counterpart. The technology not only supports real-time analytics and decision-making but also extends to predictive maintenance, performance monitoring, and product design enhancements, opening up new potentials for efficiency and innovation.

One notable potential of digital twins lies in their scalability. As technology evolves, the complexity and number of assets that can be mirrored digitally increase, offering more comprehensive insights and optimization opportunities across various sectors.

Applications of Digital Twins in Industry

Digital twins are becoming increasingly vital across several industries, from manufacturing and automotive to healthcare and urban planning. In manufacturing, they streamline production processes and enhance product quality by predicting potential system failures before they occur. In healthcare, digital twins of organs can assist in planning surgeries and predicting patient outcomes.

Moreover, in the realm of smart cities, digital twins enable city planners to optimize traffic flows and energy consumption, significantly improving urban infrastructure management. The technology’s versatility also extends to sectors like agriculture and energy, where it helps in resource management and maintenance planning.

Requirements for Implementing Digital Twins

Implementing digital twins requires robust IoT infrastructure, capable of handling extensive data collection and analytics. This includes advanced sensors, reliable data transmission systems, and powerful data processing capabilities. Additionally, a skilled workforce knowledgeable in areas like machine learning, data analysis, and system integration is essential to leverage the full potential of digital twins technology.

Another critical component is cybersecurity measures. As digital twins often involve sensitive data and critical operations, ensuring data integrity and securing communication channels are paramount to prevent potential breaches and ensure the technology’s reliability.

The Future Outlook for Digital Twins Technology

The future of digital twins technology appears promising. With advancements in AI and machine learning, the accuracy and capabilities of digital twins will only enhance, allowing for more detailed and precise simulations. This progression will likely lead to even broader applications and deeper integration into business and operational processes, signaling a significant shift in how industries operate.

Is Digital Twins Technology Here to Stay?

While some may question the longevity of digital twins technology, considering it as just another industry hype, the consistent investment and research into its development suggest otherwise. The substantial benefits it offers in improving efficiency, reducing costs, and enhancing product and service quality make it a valuable tool likely to sustain its relevance and expand its influence in the foreseeable future.

The growing adoption across diverse industries further supports the view that digital twins technology is not just a passing trend but a transformative approach destined to reshape the future of digital landscapes.